Track and control your production.Collect data with your existing assets and evaluate it.Digitize your warehouse system.AND ALL FROM ONE SYSTEM. KOMBO is a flexible framework that can be customized to individual company needs, connecting and complementing your existing systems.

KONTAKT-Elektro Kft. has been engaged in the production and construction of electrical equipment for more than 40 years, in connection with which other business lines have been established in the fields of design, contract manufacturing and IT in recent decades. As the next step in our development, we have become a Tier 2 automotive supplier with mass-produced products from 2023.

We have not found a turnkey solution on the market that can cover such a wide range of diverse operations while maintaining our well-proven solutions, so we decided to create a framework system to supplement our existing systems.

This framework system became the Kontakt Manufacturing Box, or KOMBO, which supplements the operation of existing systems (ERP, production organization, working time registration, etc.) with new, necessary functions (MES, WMS, document management, etc.) and makes our company’s operations more efficient and digital.

Framework

The framework itself already contains all the software units that are generally required for every application solution:

- users, permissions

- languanges, dictionary

- notifications

- views/topics

- license management

- modul management

Moduls

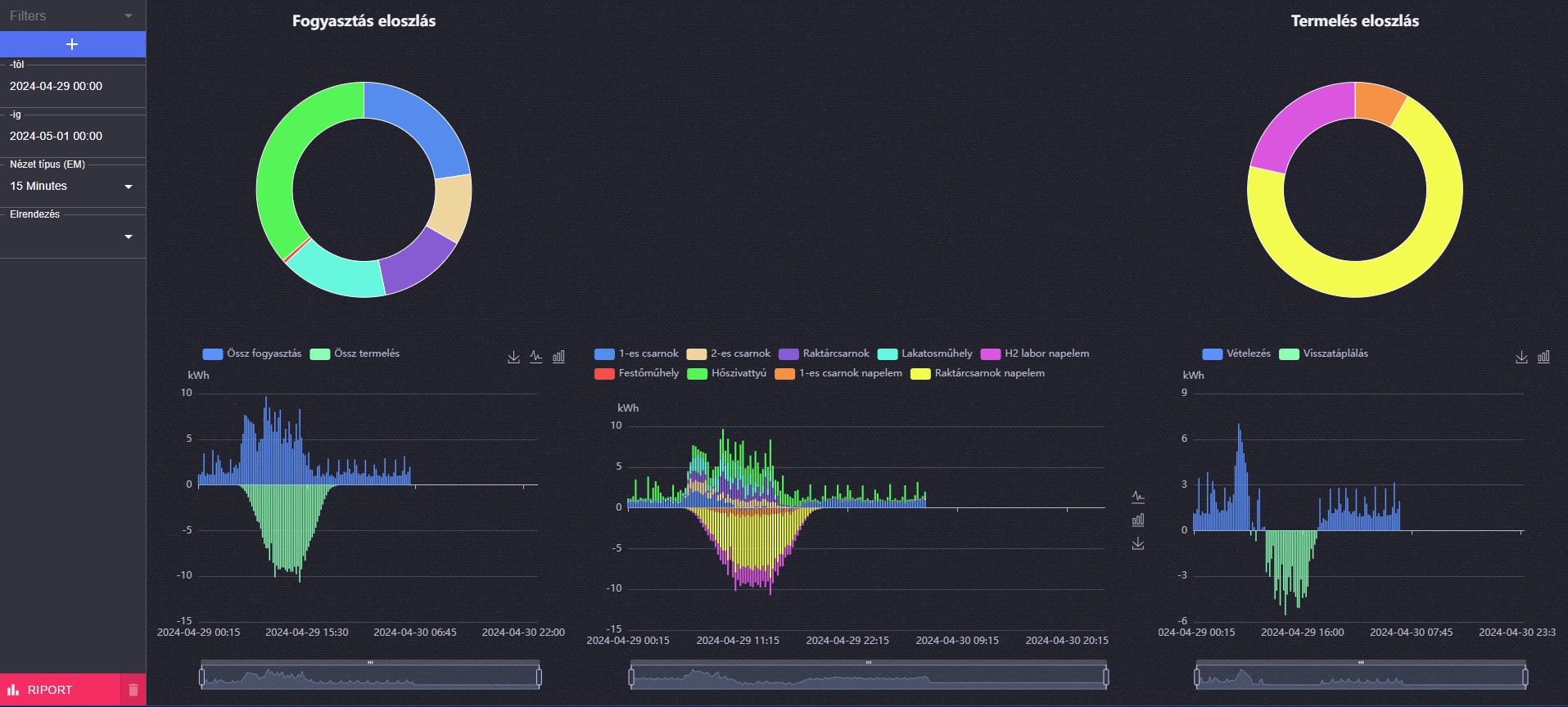

- Production data

- Downtime

- Machine utilization, OEE

- Measurement data Statistics

“Manufacturing execution systems (MES) are computer systems used in manufacturing to track and document the transformation of raw materials into finished goods. MES provides information that helps manufacturing decision makers understand how to optimize current conditions in the plant to improve production performance. MES acts as a real-time monitoring system and allows for control of multiple elements of the manufacturing process (e.g., inputs, personnel, machines, and support services).” –Wikipedia

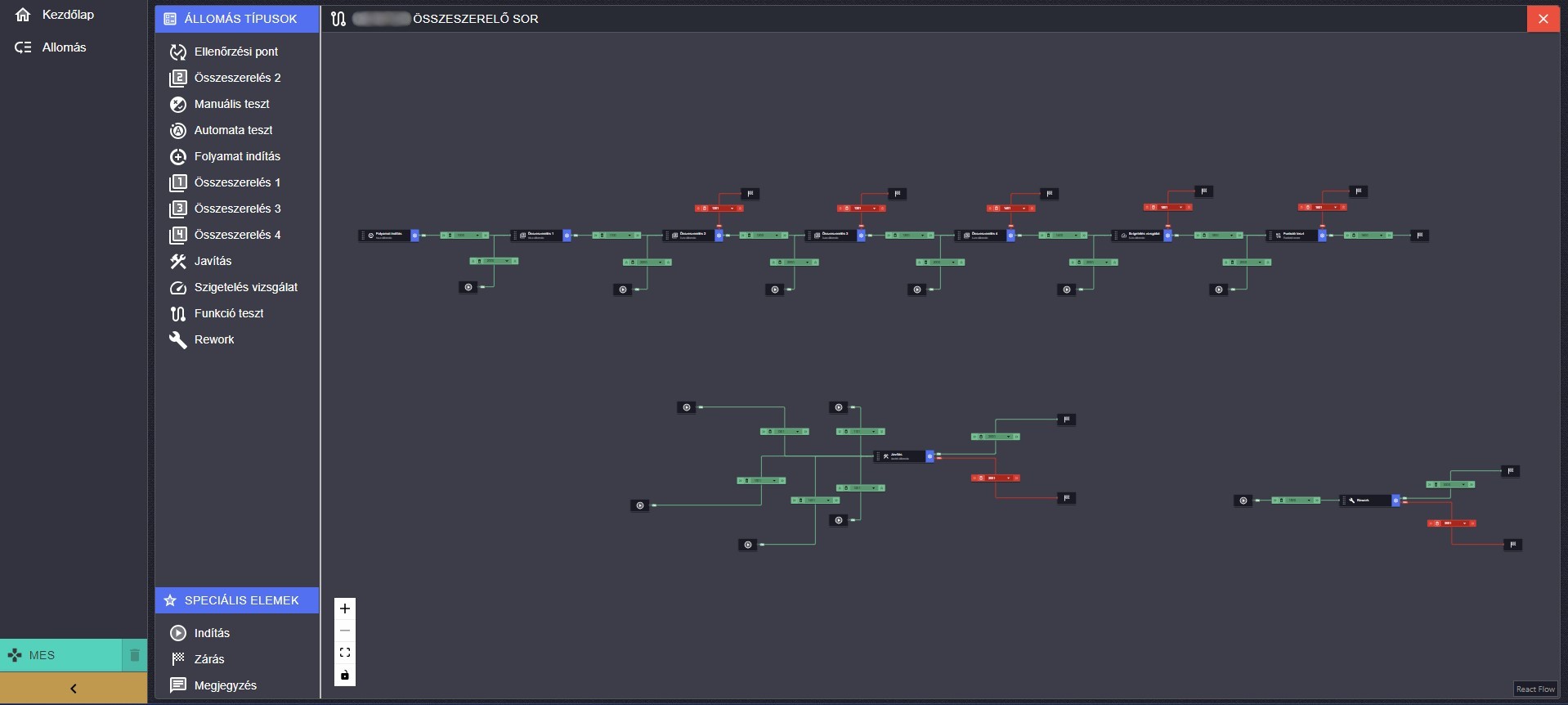

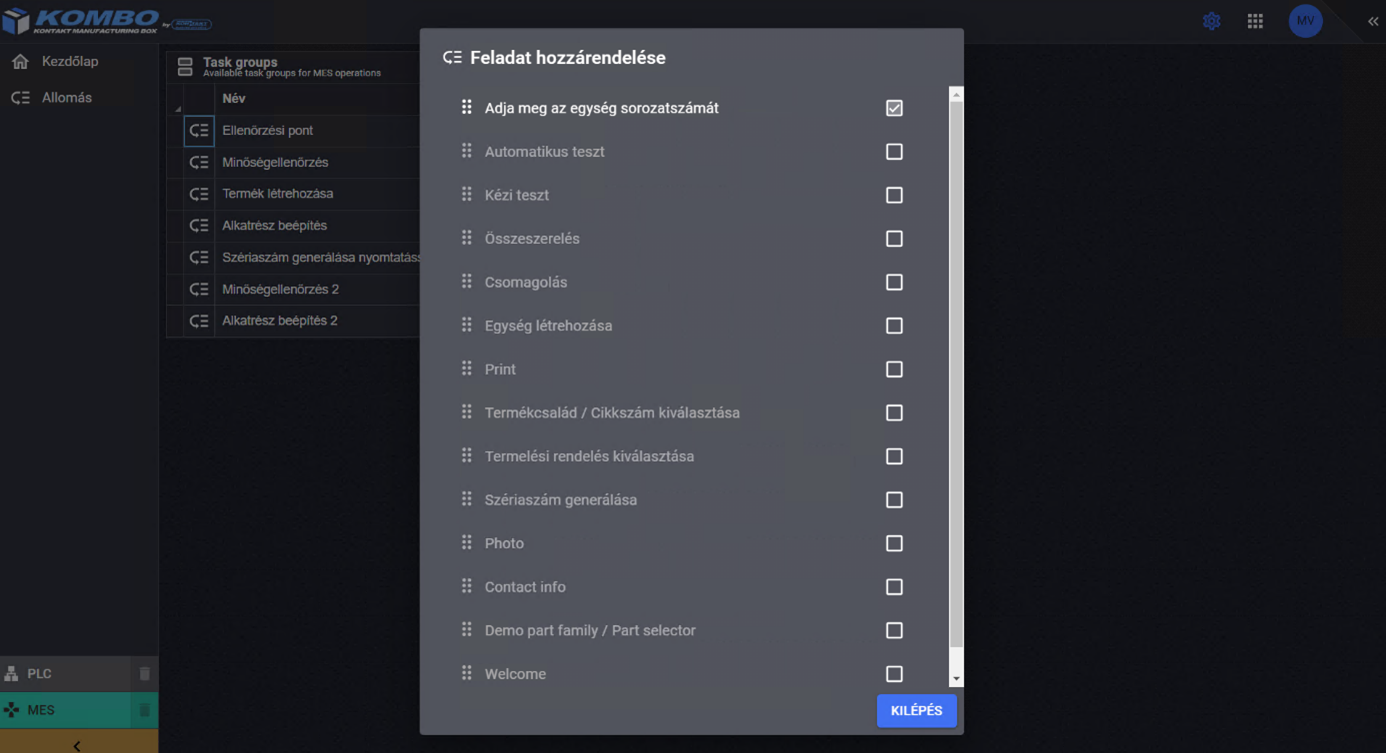

The module has the following functionality:

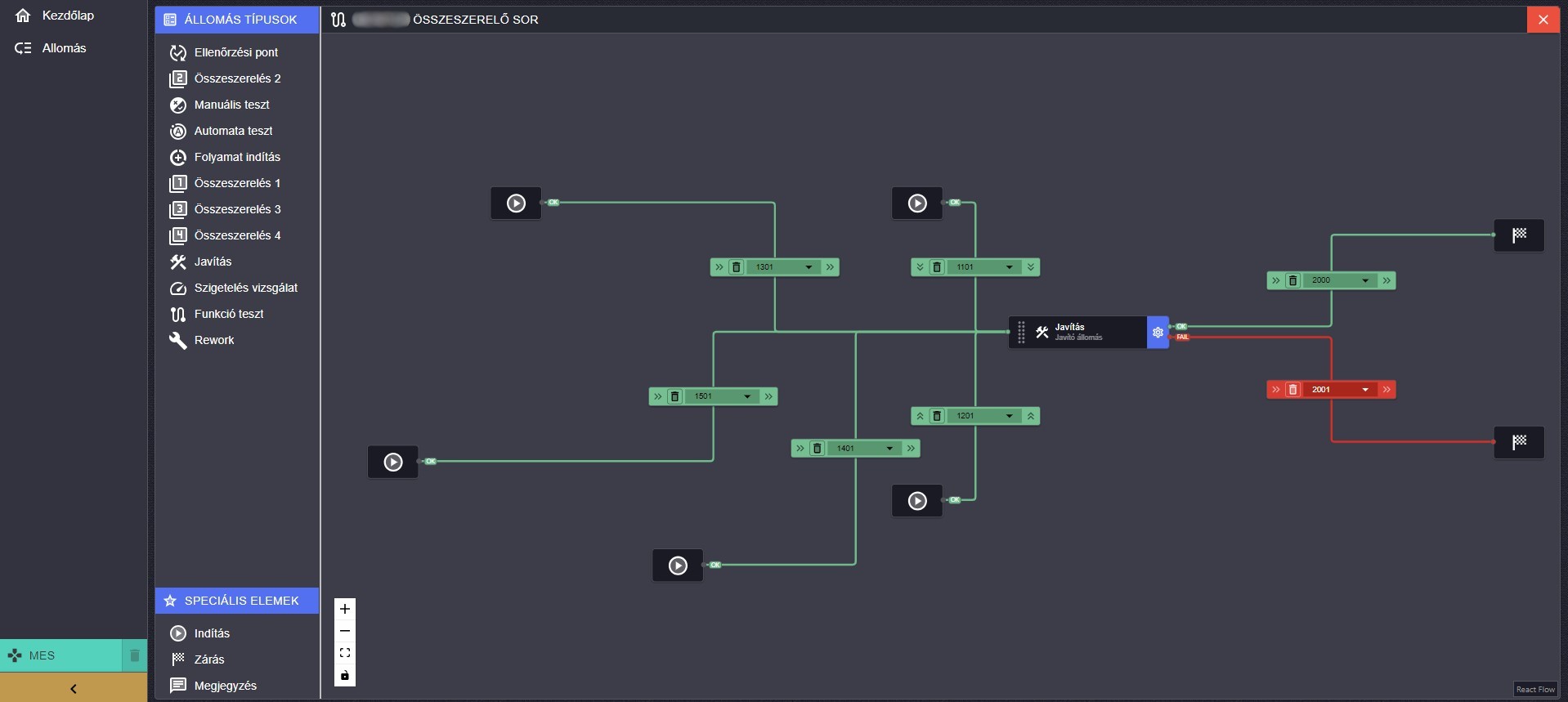

- a graphical editor is available for defining (routing) and breaking down the production processes of products, and for establishing their connections

- production process through production lines

- production lines with production stations

- production stations with elementary production steps

- production process tracking along the defined elementary steps with the following functions

- product identification

- operator operations

- machine operations

- inspections, measurements

- product tracking (traceability)

- product counting

- product routes

- quality parameter tracking

- waste management, routes, procedures

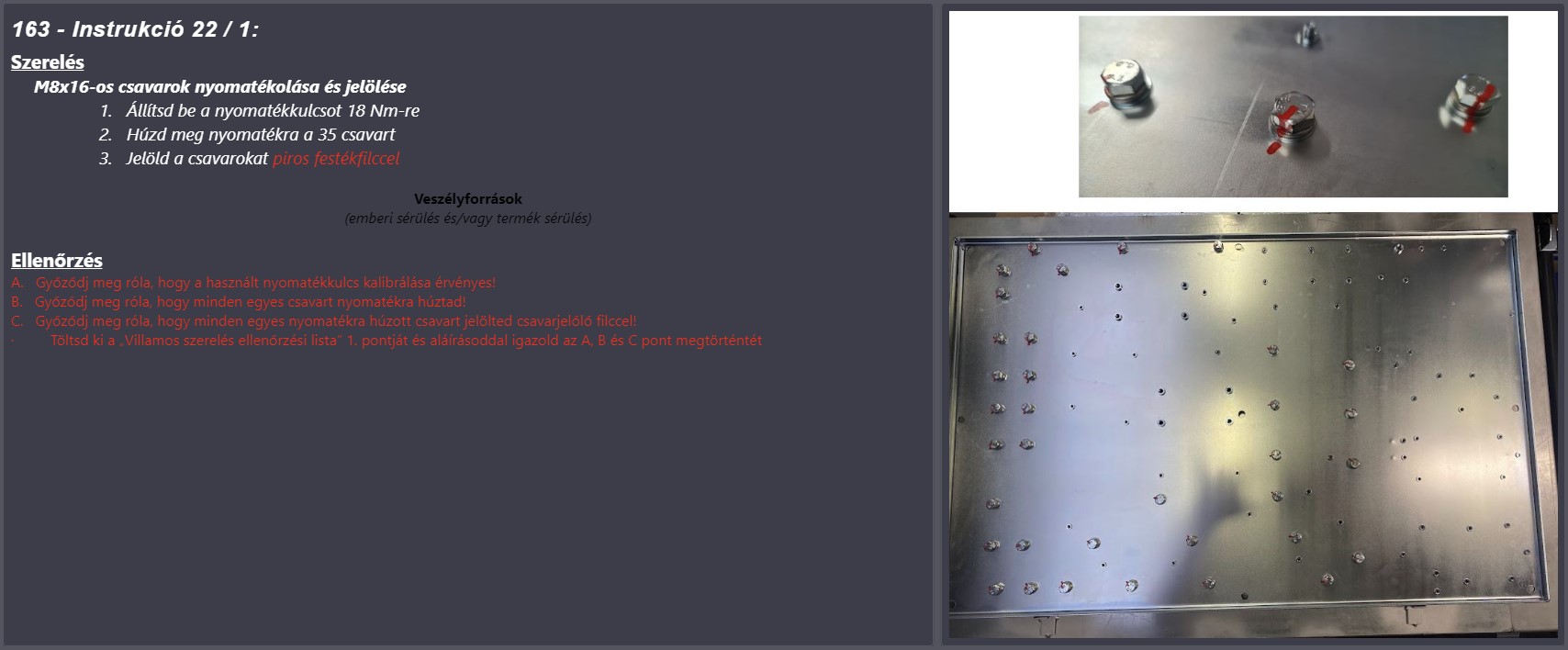

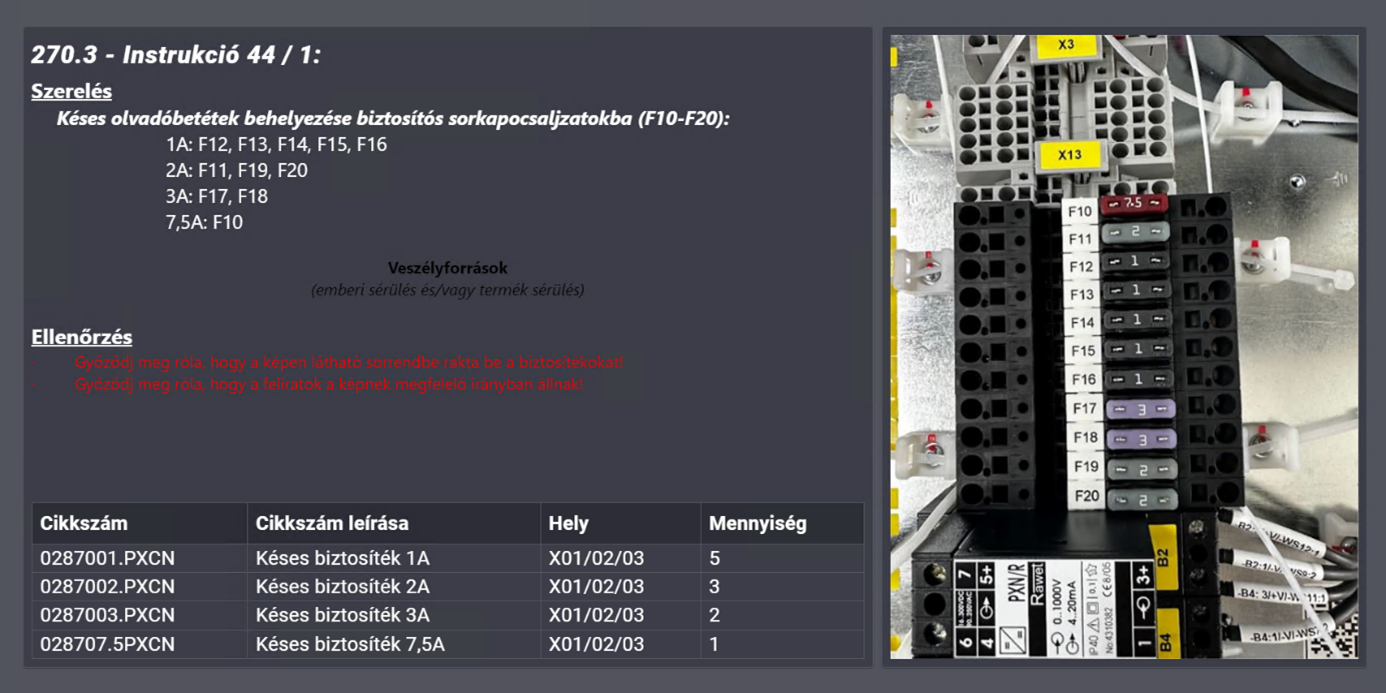

- in the case of the part of the elementary steps that the operator performs (manual assembly), a graphical interface can be created to provide the operator with information and instructions

- text instructions

- photos

- safety warnings

- component listing

- pick-to-light

- KOMBO logs all interactions and events, stores the resulting data and files; this includes

- operators

- shifts, times

- machine conditions

- components

- products

- inspections, measurements

- quality assurance data

- photo documentation

- KOMBO reports production-related data during production

- finished product

- component usage

- scrap product

- operation times

- operators

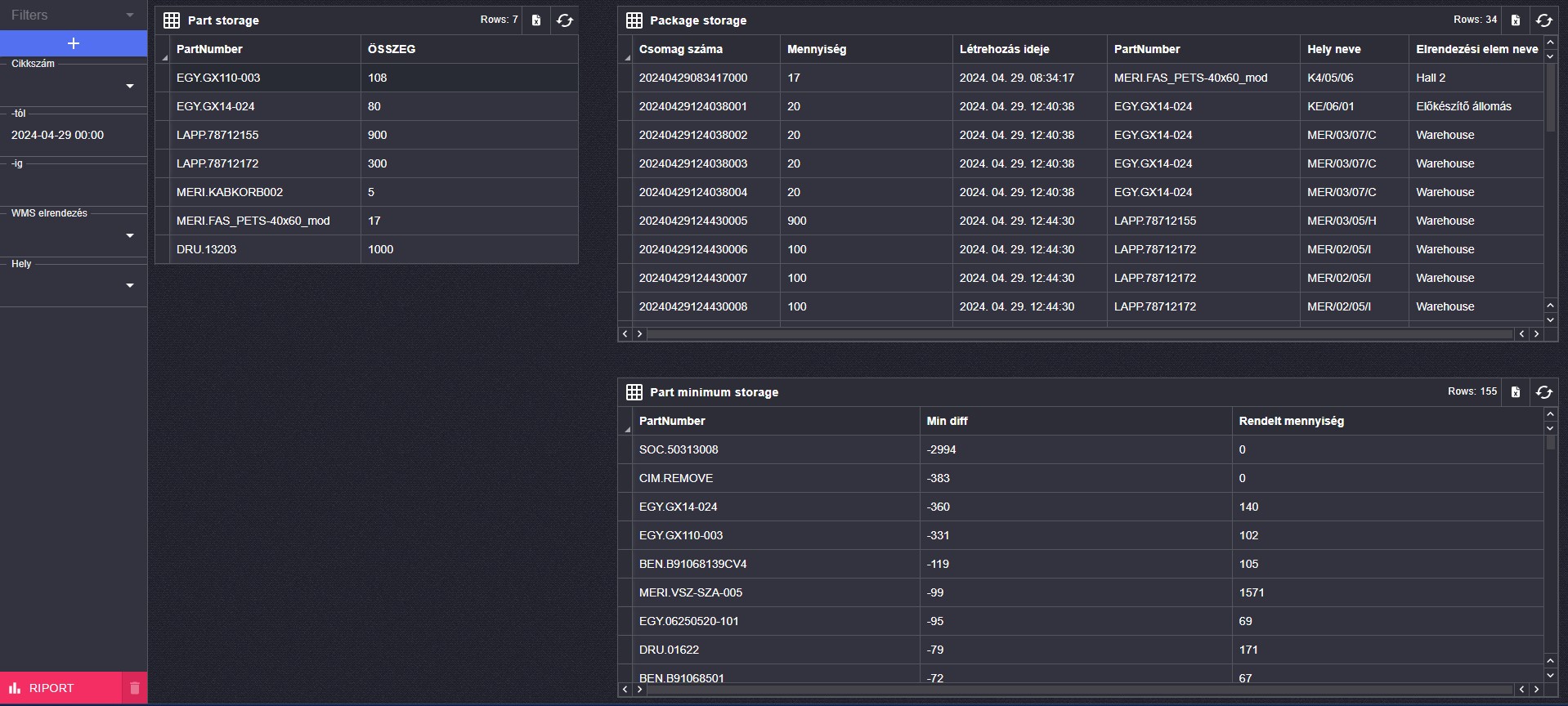

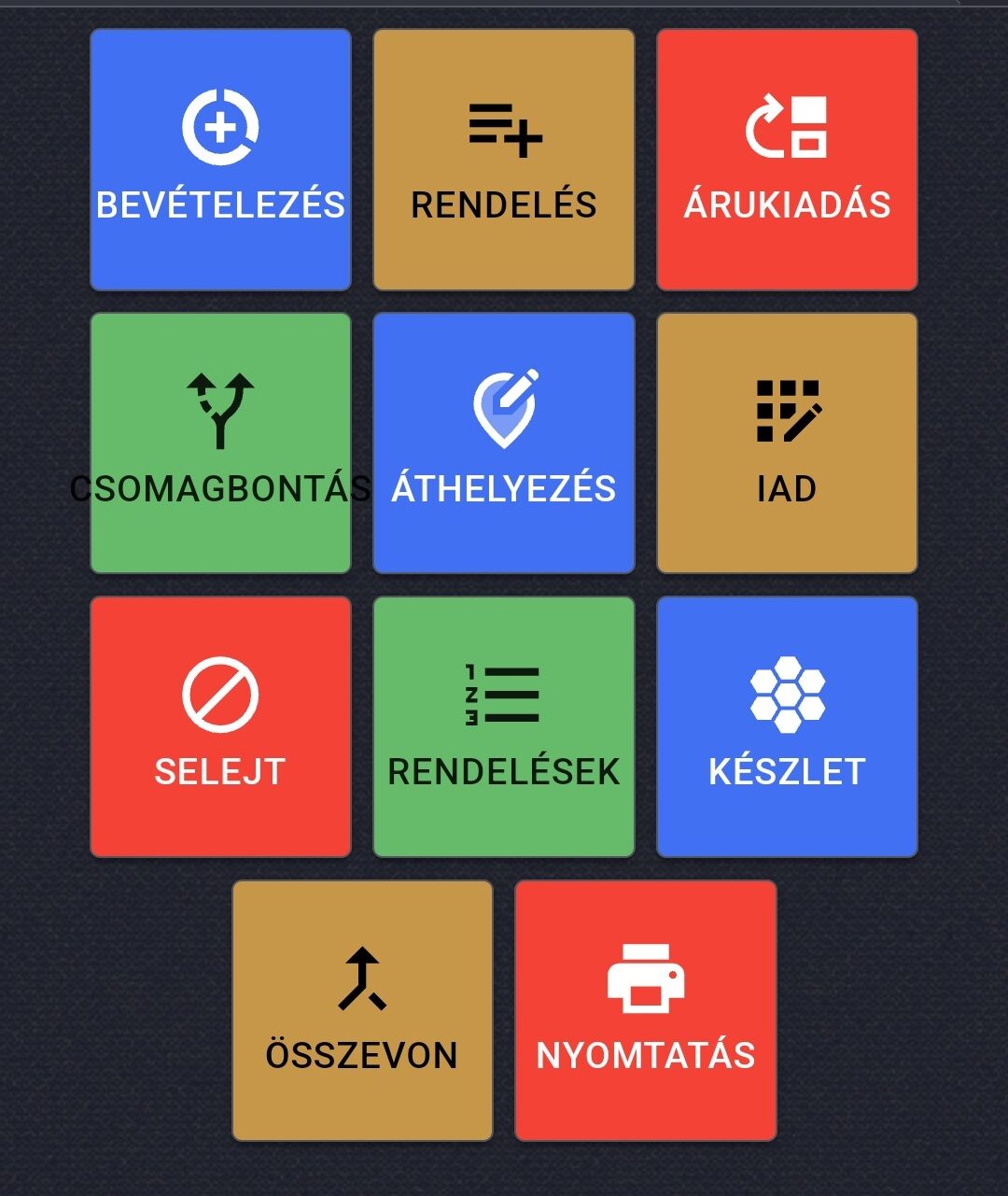

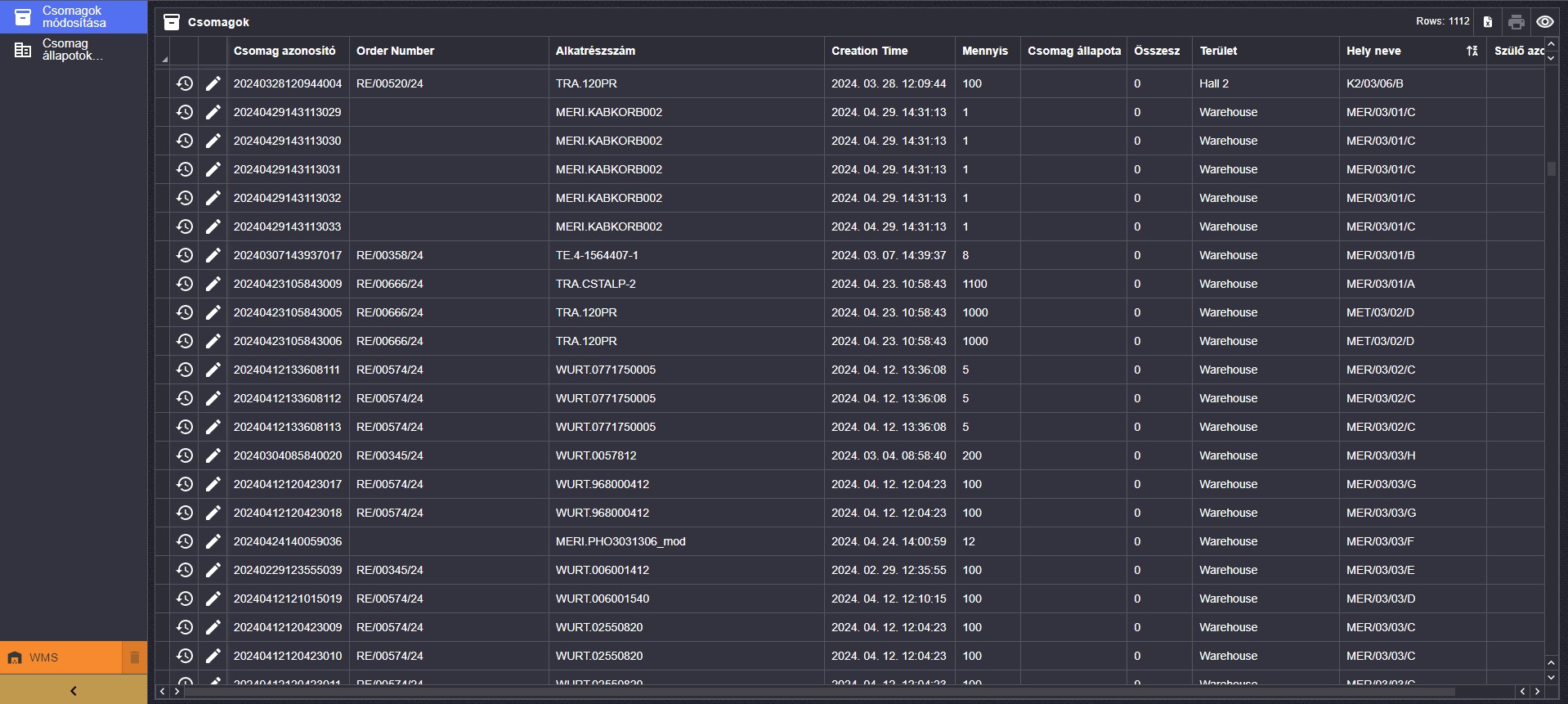

“A warehouse management system (WMS) is a set of policies and processes designed to organize the work of a warehouse or distribution center and ensure that such a facility operates efficiently and achieves its goals.” –Wikipedia

A WMS (Warehouse Management System) is a software system designed to support the efficient operation of warehouses. It aims to optimize and automate the processes that take place in a warehouse, thereby increasing efficiency, reducing costs, and improving inventory accuracy. A WMS offers various functions and tools that cover all stages of the warehousing process.

The most essential functionalities are as follows:

- Receipt and Receiving:

- Receipt: The receipt and inspection of goods. This includes registering incoming goods, quality control, and managing incoming documents.

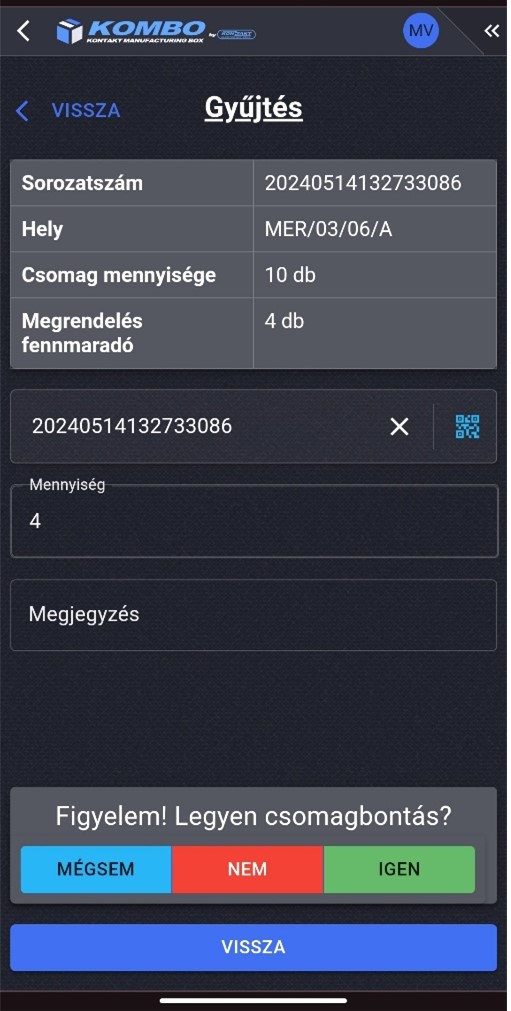

- Putaway: The movement of received goods to the appropriate storage location in the warehouse.

- Storage and inventory management:

- Storage optimization: Determining the optimal storage location for goods in the warehouse, taking into account storage capacity.

- Inventory control: Continuous monitoring of inventory, including incoming and outgoing goods, and warehouse movements.

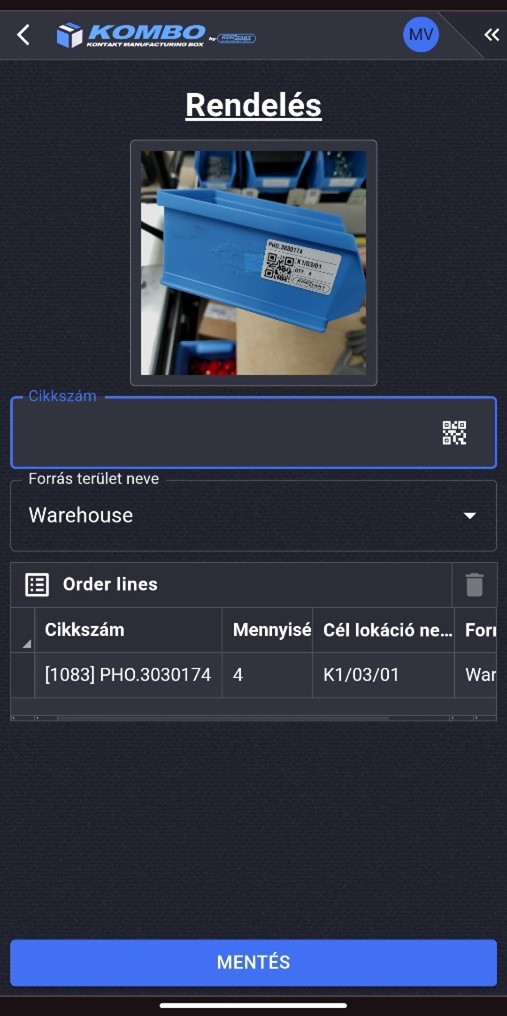

- Ordering products on the production line in case of shortages via KANBAN, Kitting system.

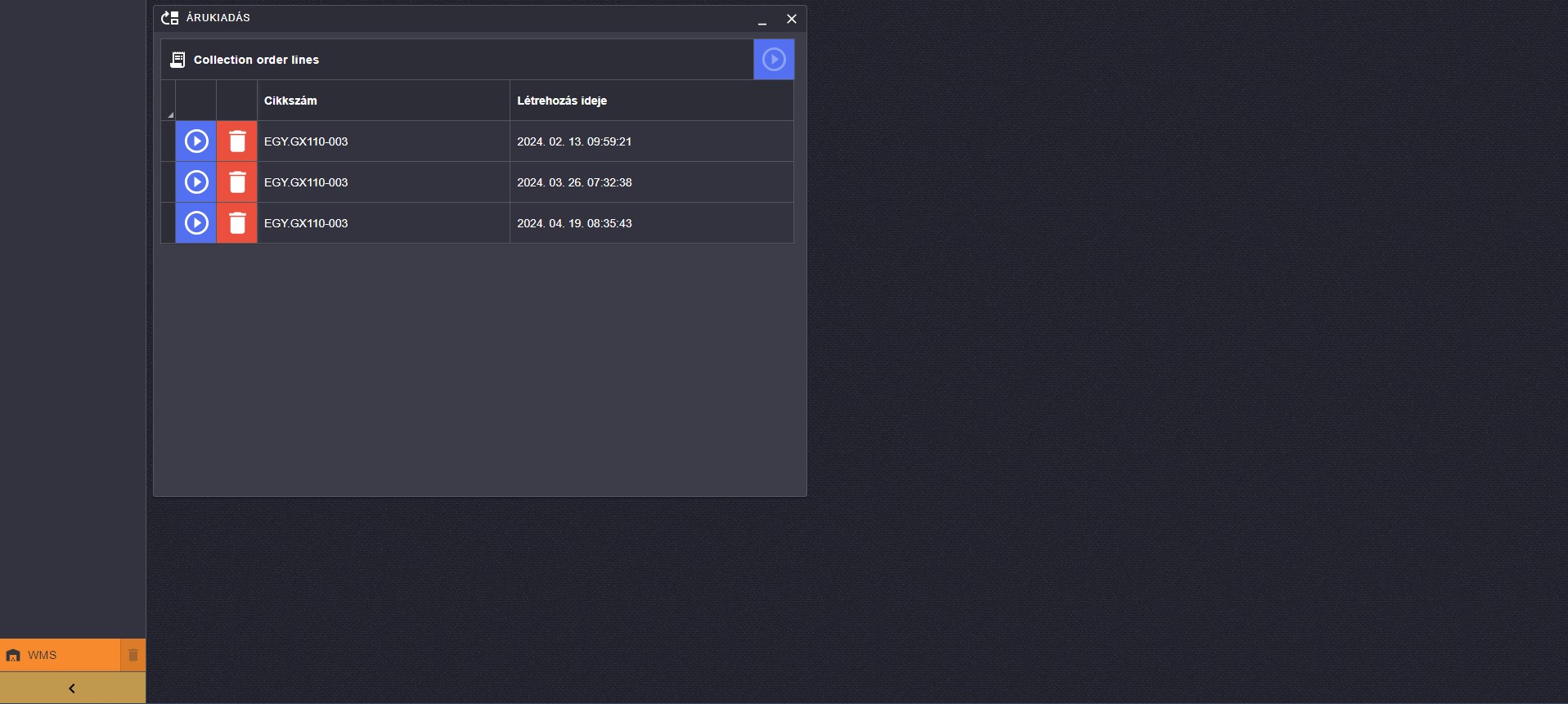

- Delivery and order processing:

- Order selection and product placement at the ordered location (Picking): Selecting goods from the warehouse to fulfill orders according to FIFO.

- Inventory control and control:

- Inventory: Regularly checking and recording the goods stored in the warehouse to ensure inventory accuracy.

- Inventory optimization: Optimizing the amount of inventory to avoid excess or shortage of inventory (MIN-MAX inventory).

- Reports and analysis:

- Performance indicators (KPI): Measuring the efficiency of warehouse processes with various performance indicators.

- Data Collection and Analysis: Collect and analyze data from warehouse operations to support decision-making.

- Integration with other systems:

- ERP systems: WMS can be integrated with enterprise resource planning (ERP) systems to connect warehouse data with other processes in the company.

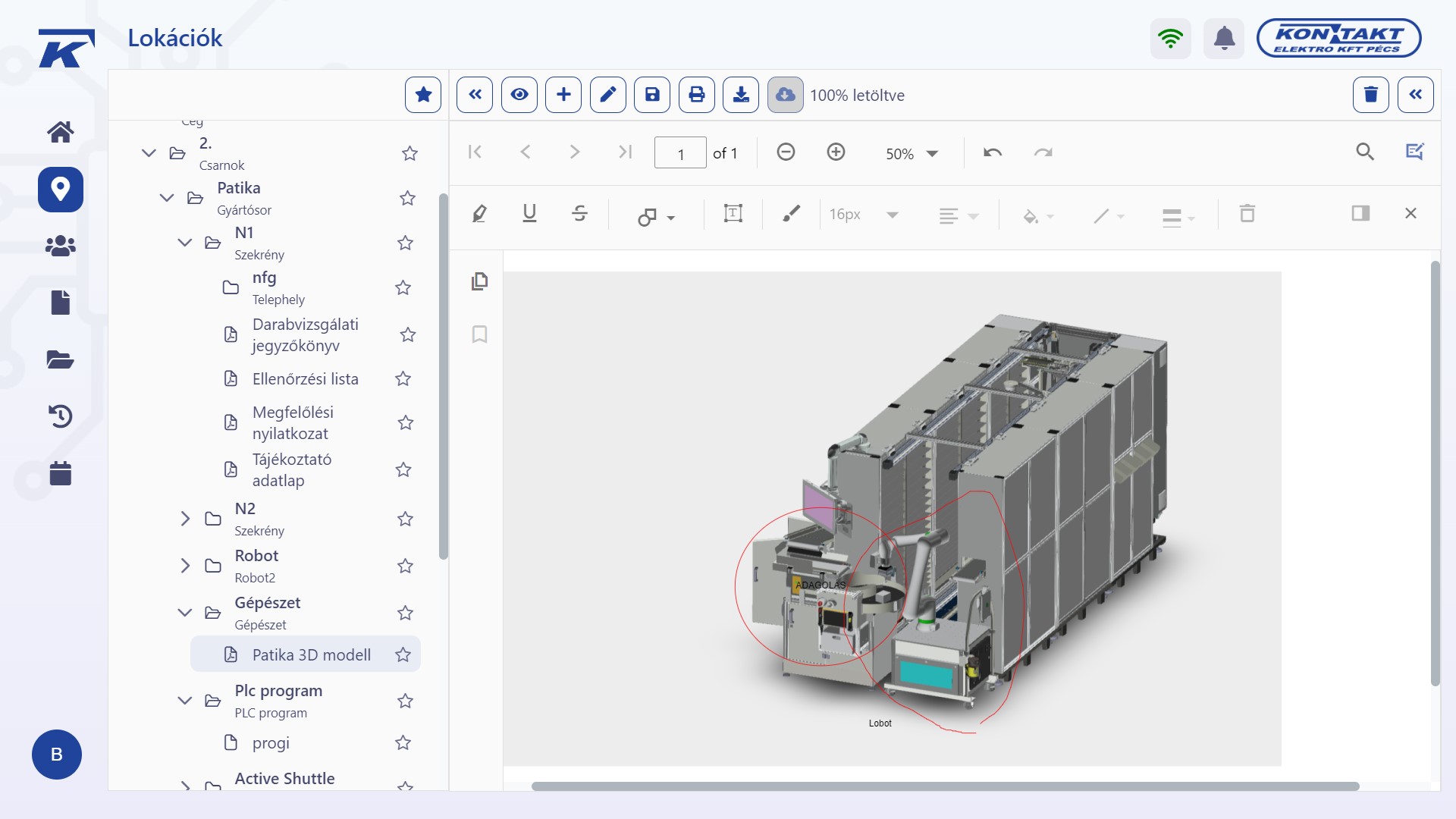

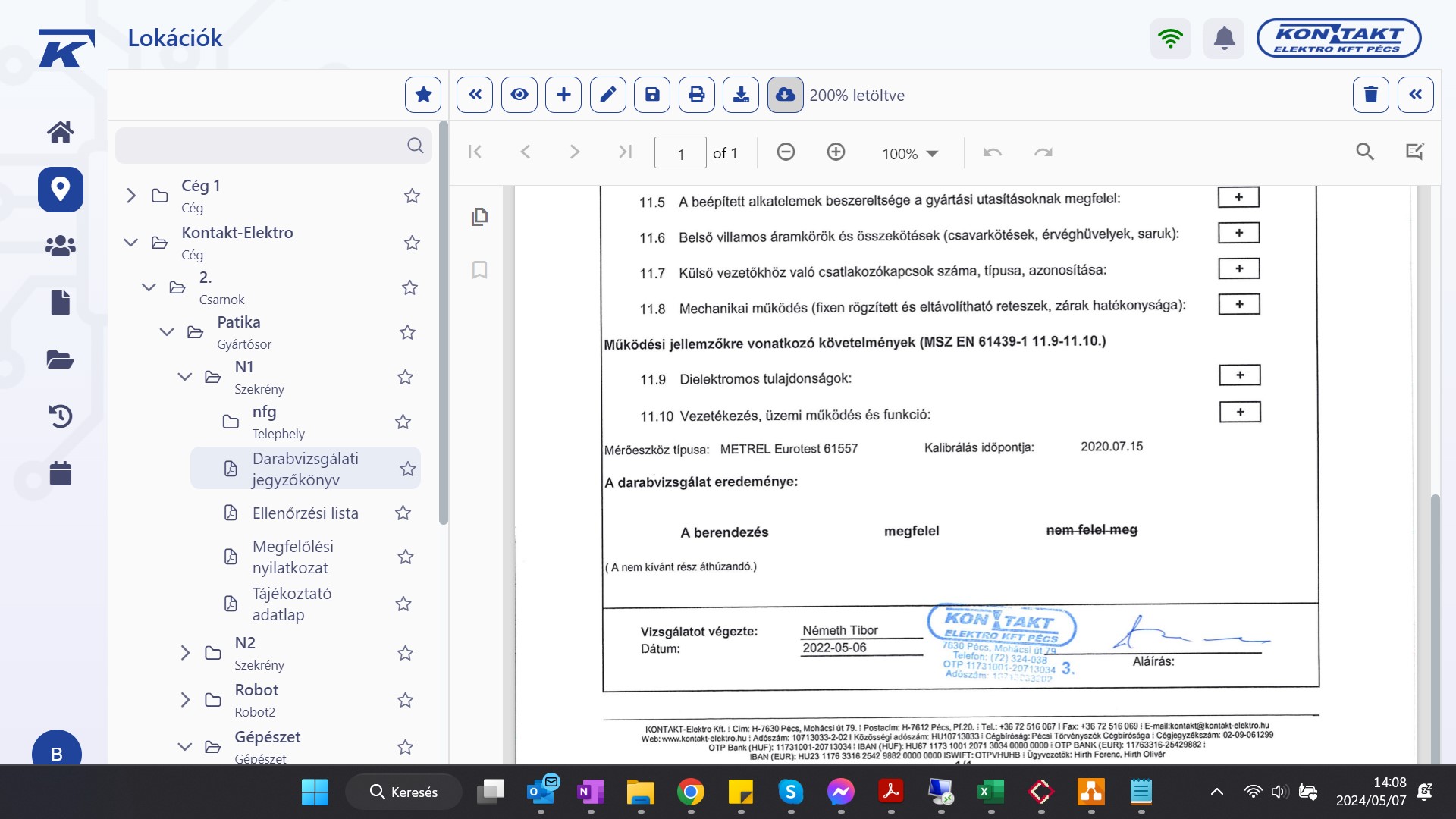

In our work, we pay great attention to the management of documentation so that it is always up to date. Minor or major modifications or corrections are often necessary in the resulting documentation and documents, as well as the management of the entire documentation and accompanying files.

Based on the feedback from our partners and colleagues, we develop a system that provides a transparent, traceable and flexibly adaptable solution for the management of all types of electronic files – with the help of modern mobile and data processing technologies.

Requirements

Software and hadware

The KOMBO software package operates in a Docker environment, its connected database is MS SQL Server. Teamcity is also recommended for smooth updates.

Due to the Docker environment, the KOMBO software is platform independent, from a hardware perspective, a server-level environment is highly recommended for medium and large systems.

The display is web-based, optimized for the Google Chrome browser in a Windows environment, and the Chromium browser in a Linux environment.

Peripherals

The KOMBO Link module allows you to connect to the typical device by default. The types of connectable devices and the communication protocols supported are constantly expanding, and custom protocols can also be created upon request.

Typical devices and connections:

- (industrial) PC (ethernet)

- Raspberry PI (ethernet)

- Barcode and QR code reader (USB)

- Printer (ethernet)

- Industrial controllers / measuring instruments

- (ethernet OPC-UA, Modbus TCP, S7, MQTT)

- Pick-to-light (wireless)

- ERP

- MS Excel

Let your imagination run free

KOMBO is a flexible tool that can be completely customized to your needs.

You can also request a function that is not currently available in KOMBO modules.

Every company's operation is unique and therefore we always adapt KOMBO to these unique needs.

LET'S GET IN TOUCH!

Contact us and our expert colleagues will make a proposal for your own, unique COMBO after assessing your individual needs.