Development projects by KONTAKT-Elektro Ltd.

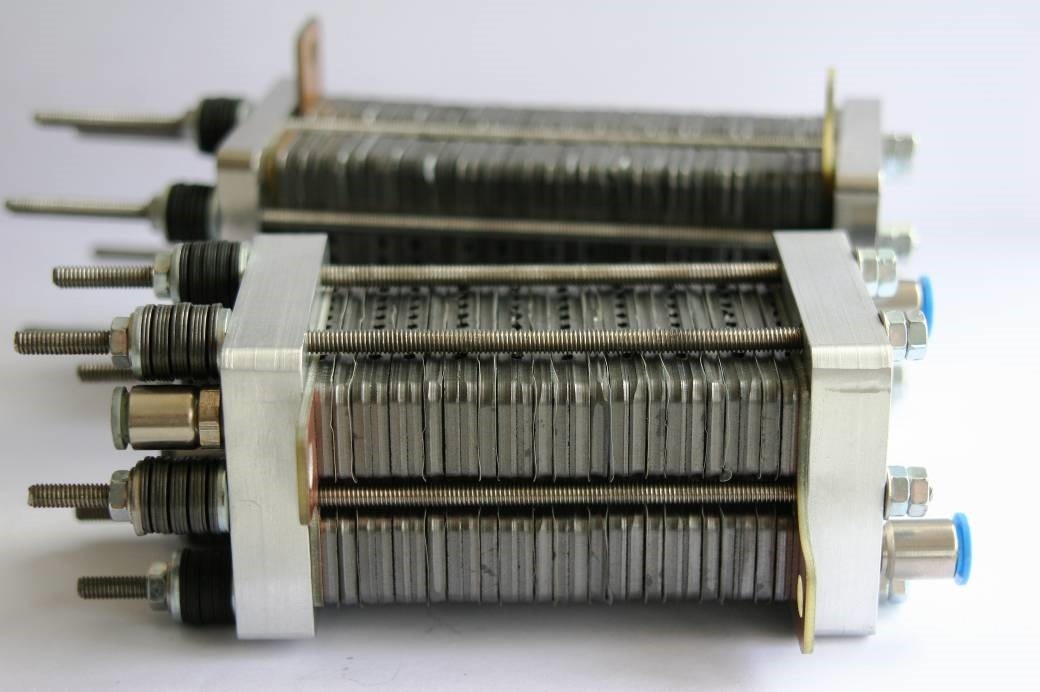

Our company started dealing with fuel cells 15 years ago. This first development result of the company in this field was the production of a 100W fuel cell stack, which was implemented in 2007 in the framework of an INNOCSEKK tender. Next step was to develop the first stack further and changing as many of its components to own developed ones as possible. This was made possible by the GOP tender in 2010 which we won in cooperation with the MTA Chemical Research Institution (later MTA TTK Material and Environmental chemical institute). During the project using the anode catalyst without platinum developed by the MTA KKI as base we were able to produce fuel cell stacks in several versions and sizes. (Katalizátor_MEA). The stacks ranging from 10W to a couple of kW were 10 cm2, 50 cm2, 100 cm2 and 200 cm2 active surfaced open and closed, air and liquid cooling versions were produced (Stack prototypes). The BiPolar plates used for the stacks were graphite based composite plates, part of which were produced by the BME Polymer technology Department (BiPolar plates).

Parallel to the development of the stacks, Kontakt-Elektro Ltd also started developing fuel cell based facilities. Our first facility was a 300W portable power supply tool, that we developed specifically for the power supply of small electric boats. Besides the case we also installed a metal-hybrid hydrogen storage built into a portable frame which is able to supply the device with hydrogen for about 6 hours (portable power supply).

We launched a bigger project in 2010 in the topic of equipment development, for which we won the support of Gábor Baross tender together with the Faculty of Engineering and Information Technology of the University of Pécs. The aim of the project was to build the prototypes of stationary and portable applications until 5kW performance based on fuel cell. To realize the project, we were planning to use the market stack, this is how we got to know the Canadian Ballard company, who is and has been a leading producer of fuel cells since its launch (power sources based on Ballard stack).

The first prototypes which was based on the Ballard stack was a bicycle powered by a 400W fuel cell (fuel cell bicycle). After this, we built a 3kW uninterrupted power supply designed for 48VDC systems, which a similar performance, accumulator based hybrid power source facility followed. Later this hybrid power supply was the base of the power supply of the fuel cell boat which was introduced in 2013 on the Boat Show of Balatonlelle (FC ship). Besides the Ballard FCgen-1020ACS air cooling stack family, we used the company’s FCgen-1310 types of liquid cooler stack as well in two other facilities: we made a 4.5kW uninterrupted power supply, and a similar performance, cogeneration (capable of heat and electricity production) facility. Besides the items listed above, we advised the Orca racing car designed for the international ECOMarathon competition built by the university, the first version of which was supplied by the 1.2kW stack built by our company.

Besides the fuel cell facilities, we also deal with other connecting hydrogen technologies as well. In 2012, we built an electrolyte facility supplied hydrogen recharge container which was powered by solar panels, with which we were able to fill hydrogen to cylinders until 300 bar using explosion secure, pneumatic power pressure enhancing from the 15bar buffer containers (Hydrogen recharge station powered by solar panel). Developing the previously mentioned concept further in 2013, we built an autonomous energy container, which operates consumers using electricity and solar panels, using energy surplus it creates hydrogen which they store in a 30bar buffer container, where in case of power outage electricity is produced by fuel cell above the need of the power solar panels can supply (Energy container). To demonstrate similar power supply scheme, we built a facility that rolls on wheels, in which we integrated electrolyzing facility and fuel cell, with inverter and solar panel connecting possibility (hydrogen energy container facility).

Over the years we have gathered experience, which moved our focus form developing fuel cell stacks to purchasing facilities and developing them further, which was less time-consuming, gave us the opportunity to put it on the market faster, though the knowledge we gathered while developing the stacks and their components became invaluable when building the purchased stacks further, by providing the perfect operating conditions and designing the BOP (Balance of Plant) system necessary for operation.

After the tender projects, we saw business opportunity in mainly the installed applications, more specifically the uninterrupted power supplies, so we continued developing in this field. In 2014, we finished building a modular, rack based uninterrupted power supply which we were able to sell on the market (FC-UPS 2500 – introduction).

After the upturn of fuel cell technologies in 2017 we rebuilt our contact with a cell producer company, and were able to purchase a 15kW, modern fuel cell module from Hydrogenics, using which we could aim for the performance range above 10kW. Our first equipment was a 15kW power supply which rolled on wheels, which was perfectly capable of providing energy for concerts, festivals, and movie productions due to its noise strain and zero emission (FCPS-15 – introduction).

Other area where we used the module of Hydrogenics was a little ship designed for recreational purposes which uses a 15kW electric engine and an accumulator-fuel cell hybrid power supply system, where the hydrogen supply is rechargeable using a 300bar composite cylinder storage system (H2-evolution yacht). This yacht was introduced in September 2020, on the Boat Show of Balatonkenese.

Our plan for the future is to develop a bigger ship based on the 15kW small ship (Hydrogen based electric yacht), and the prototype of a waste collecting vehicle (Municipal and commercial vehicles).

You can download the information sheet about our own developments by clicking on the following links:

- Catalyst MEA

- Stack prototypes

- BiPolar plates

- Portable power supplies

- Power supplies based on Ballard stack,

- Fuel cell bicycle,

- Fuel cell ship

- Solar panel powered hydrogen power station,

- Energy container

- Hydrogen energy storage facility

- FC-UPS 2500 – introduction

- FCPS-15 – introduction

- H2-evolution yacht

- Hydrogen powered electric yacht,

- Municipal and commercial vehicles